Call: 08045477320

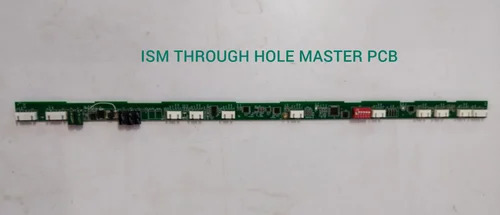

Individual Spinning Production Monitoring System

Price 18500 INR/ Unit

MOQ : 1 Unit

Individual Spinning Production Monitoring System Specification

- Size

- 250 mm

- Features

- High Quality

- Mounting Type

- In Textile Machine

- Material

- Plastic

- Usage

- Industrial

- Warranty

- Yes

Individual Spinning Production Monitoring System Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

- Main Domestic Market

- All India

About Individual Spinning Production Monitoring System

Experience commanding efficiency with our Individual Spinning Production Monitoring System, crafted for discerning textile manufacturers and industrial operators. This exceptional system, sized at 250 mm and expertly mounted on textile machines, seamlessly tracks production data to deliver enviable control over operational output. Manufactured from high-quality plastic, it offers both durability and reliability, guaranteed with a lasting warranty. As a manufacturer, service provider, supplier, and trader in India, we present an ephemeral opportunity. Take advantage of our competitive savings and secure superior monitoring for your textile processes today.

Versatile Usage in Textile Production

The Individual Spinning Production Monitoring System is primarily used as a real-time solution for overseeing and enhancing spinning production in industrial environments. Its usage type is dedicated to in-textile machine mounting, ensuring accurate and uninterrupted monitoring throughout the process. Specifically designed for use in textile manufacturing, this system delivers reliable data to optimize operations and boost efficiency, making it an indispensable tool in modern textile mills and processing units.

Premium Packaging and Domestic Reach

Our main domestic market encompasses key textile hubs across India, providing swift handover of orders with secure, premium packaging. Each Individual Spinning Production Monitoring System is processed with meticulous order processing routines, ensuring that you receive certified and thoroughly inspected products. Our certifications underscore our commitment to industry standards, making each delivery a mark of quality, reliability, and professional service for textile manufacturers nationwide.

Versatile Usage in Textile Production

The Individual Spinning Production Monitoring System is primarily used as a real-time solution for overseeing and enhancing spinning production in industrial environments. Its usage type is dedicated to in-textile machine mounting, ensuring accurate and uninterrupted monitoring throughout the process. Specifically designed for use in textile manufacturing, this system delivers reliable data to optimize operations and boost efficiency, making it an indispensable tool in modern textile mills and processing units.

Premium Packaging and Domestic Reach

Our main domestic market encompasses key textile hubs across India, providing swift handover of orders with secure, premium packaging. Each Individual Spinning Production Monitoring System is processed with meticulous order processing routines, ensuring that you receive certified and thoroughly inspected products. Our certifications underscore our commitment to industry standards, making each delivery a mark of quality, reliability, and professional service for textile manufacturers nationwide.

FAQs of Individual Spinning Production Monitoring System:

Q: How does the Individual Spinning Production Monitoring System enhance textile production?

A: This system continuously monitors spinning output, providing real-time data to increase efficiency and reduce downtime, resulting in improved production quality and savings.Q: What is the process for installing the monitoring system on textile machines?

A: The system features simple mounting directly within textile machines, with our team available to assist in installation, ensuring a seamless transition without significant machine downtime.Q: When should a textile manufacturer consider upgrading to this system?

A: Manufacturers should consider this upgrade when seeking better production control, data-driven operations, or when replacing outdated monitoring equipment for improved performance and reliability.Q: Where can this monitoring system be most effectively used?

A: It is optimally used in industrial textile environments, particularly within spinning mills, where real-time production data is essential for maintaining output and operational excellence.Q: What benefits does the product warranty cover?

A: The warranty covers defects in material and workmanship, ensuring service support or replacement to guarantee uninterrupted textile production and peace of mind.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry